|

Burst and Collapse - Pressure Vessel Design

Analysis: [calculator]

The magnitude of pressure a vessel can withstand is predicted with the von Mises combined stress model. Failure occurs when the von Mises stress exceeds the material's 0.2% yield strength.

Von Mises stress

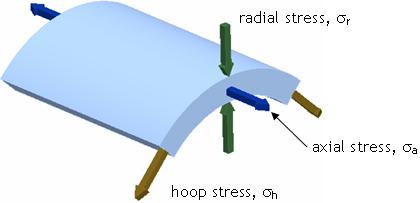

The von Mises stress is a combination of the three principal stresses (axial, radial, tangential/hoop) and the shear stress caused by torque.

Axial stress

The axial stress is caused by the pressure acting on the ends and additional forces in the axial direction. For this calculation, there is no additional axial force, but there is an axial force acting on the ends.

Radial stress

The radial stress is caused by the internal and external pressures acting through the wall. Yielding of a pressure vessel occurs at the inner surface first so the internal pressure is used for this calculation.

Hoop stress

The hoop stress can be imagined as a band surrounding a barrel. As the barrel expands, the band stretches and undergoes stress. Yielding of a pressure vessel occurs at the inner surface first so the hoop stress is calculated on the inner surface.

Shear stress

Any additional torque applied to the pressure vessel must be accounted for. Shear stress is calculated on the outer surface for a more conservative answer. For this calculation, additional torque is not applied.

|